While Carbon Steel fabricating has been and continues to be a huge portion of the projects here at Munich Welding, we have taken the opportunity over the last few decades to incorporate an increasing amount of Aluminum, Stainless Steel, and Exotic Alloys. Our internal flow and processes ensure proper welding procedures are maintained, material segregation is observed, and finishes are available to make our final products professional and appealing.

Aluminum

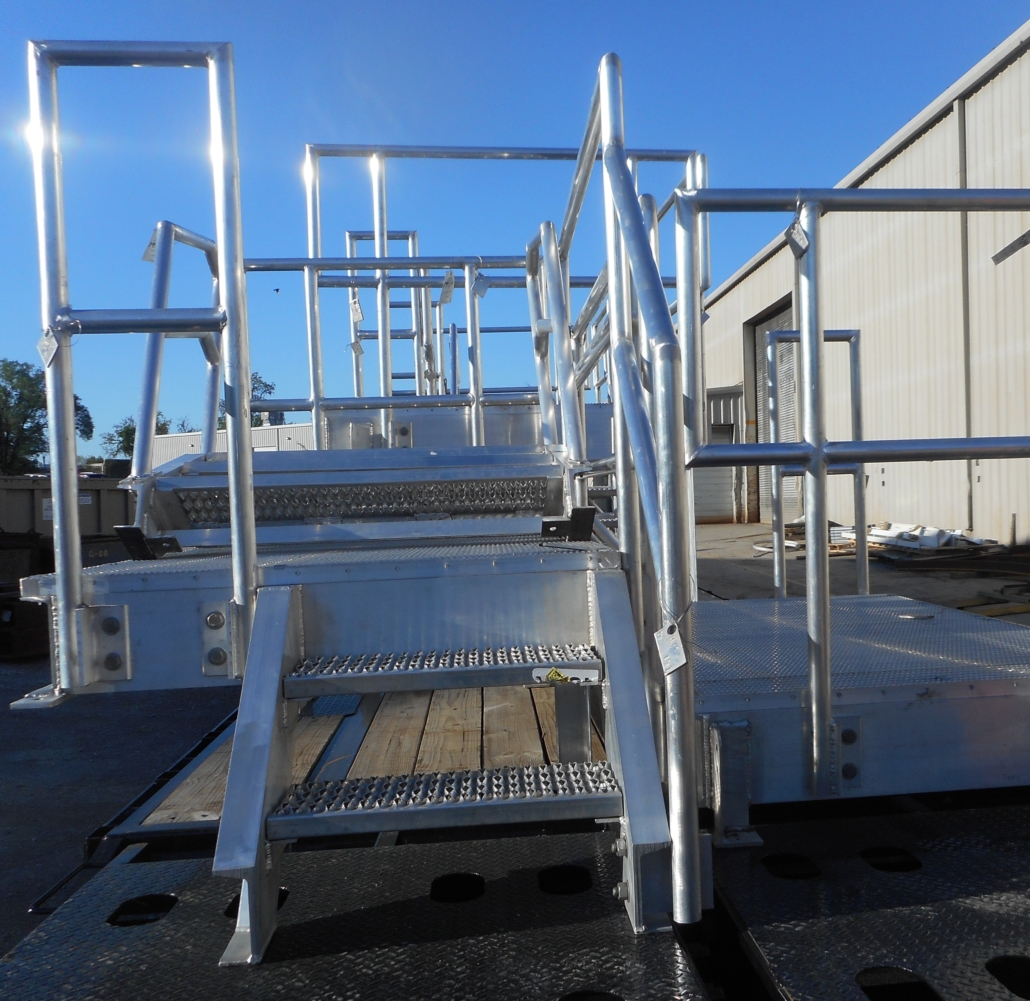

Munich Welding specializes in the design and manufacture of aluminum structural, plate and sheet fabricated items. Among the products we manufacture are:

- Aluminum Structural Support structures

- Aluminum Platforms

- Welded/Mechanical Aluminum Handrail

- Aluminum Grating

- Aluminum Plate and sheet fabrication

Munich utilizes both GTAW (gas tungsten arc welding) and GMAW (gas metal arc welding/Pulse) to ensure the structural integrity of the products we produce. Welding of these materials are reviewed by our in-house AWS Certified Welding Inspectors in conformance of AWS 1.2 welding code. Munich also has the available options for finishing these products with:

- Glass Bead Blast

- Anodizing

- Powder Coating

- Specialized painting and finishes

Whether you need 3000, 5000, or 6000 series aluminum fabrication, Munich has the expertise to meet your requirements.

Stainless Steel

As mentioned throughout our website, we go out of our way to make Stainless projects look appealing. From segregating materials in all processes (including storage) to final media blasting prior to shipment, our goal is to increase the “wow” factor when the metals show up on site. We have created projects from small gussets and brackets all the way up to large, 50+ foot long tanks from various forms of Stainless Steel.